What is DiKel?

'D' stands for Dongkuk and also signifies Decarbonize.

DiKel, a compound word of 'D' and 'Nickel,' represents Dongkuk Industries' nickel-plated steel brand, which aims for decarbonization.

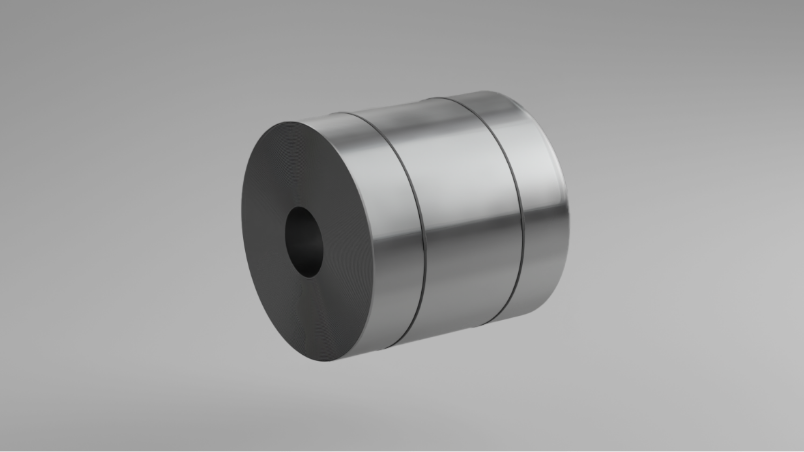

What is a Nickel-Plated Steel?

A Nickel-plated steel, known for their corrosion resistance, oxidation resistance, and workability, is used for wrapping cylindrical batteries.

The battery case made of nickel-plated steel protects the materials inside the cylindrical battery and enables electrical connections.

Why does Dongkuk Industries produce a Nickel-Plated Steel?

Over the past 50 years, Dongkuk Industries has grown into a specialty steel company with global competitiveness, actively engaging in environmental protection efforts such as installing solar power plants, establishing and adhering to environmental policies, and aggressively introducing carbon reduction facilities. The demand for environmental protection is increasing worldwide, naturally triggering changes in the production methods of major industrial markets. In response, Dongkuk Industries has newly introduced the 'Nickel-Plated Steel ' business, a material for cylindrical batteries used in eco-friendly electric vehicles, to contribute to the global agenda of 'sustainable development goals' and 'environmental protection.'

Internal Combustion Engine Cars

Electric Vehicles (EV)

Furthermore, the global electric vehicle (EV) market is rapidly growing due to rising gasoline prices and environmental issues. According to the International Energy Agency (IEA), electric cars' market share in the total automotive market grew from 4% in 2020 to 14% in 2022, and it is expected that by 2030, electric cars will account for more than 60% of the total automotive market share on average. A Nickel-plated steel plays a vital role in enhancing the stability of cylindrical batteries used in these electric vehicles.

Curious about Cylindrical Batteries Wrapped in a Nickel-Plated Steel?

Cylindrical batteries are one type of electric vehicle battery, with the main types being cylindrical, pouch, and prismatic batteries. Check out the purposes and characteristics of each battery type

| Name | Cylindrical Battery | Pouch Battery | Prismatic Battery |

|---|---|---|---|

| Photo |  |

|

|

| Material | Nickel-Plated Steel | Film | Aluminum |

| Main Uses | Electric vehicles, power tools, wireless vacuums, etc. | Electric vehicles, mobile phones, etc | Electric vehicles, mobile phones, etc |

| Advantages | Affordable price Excellent durability Ease of mass production High fire safety |

High energy density Flexible design |

Strong against impact Ease of mass production |

| Automotive Companies Using Them | Tesla, Lucid, Rivian, GM, Volvo | Hyundai, Kia, GM, Ford, Renault, Volvo | BMW, Mercedes, Audi, Volkswagen |

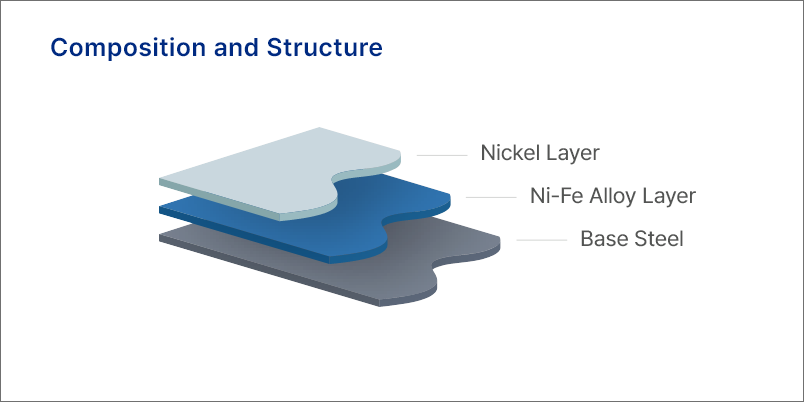

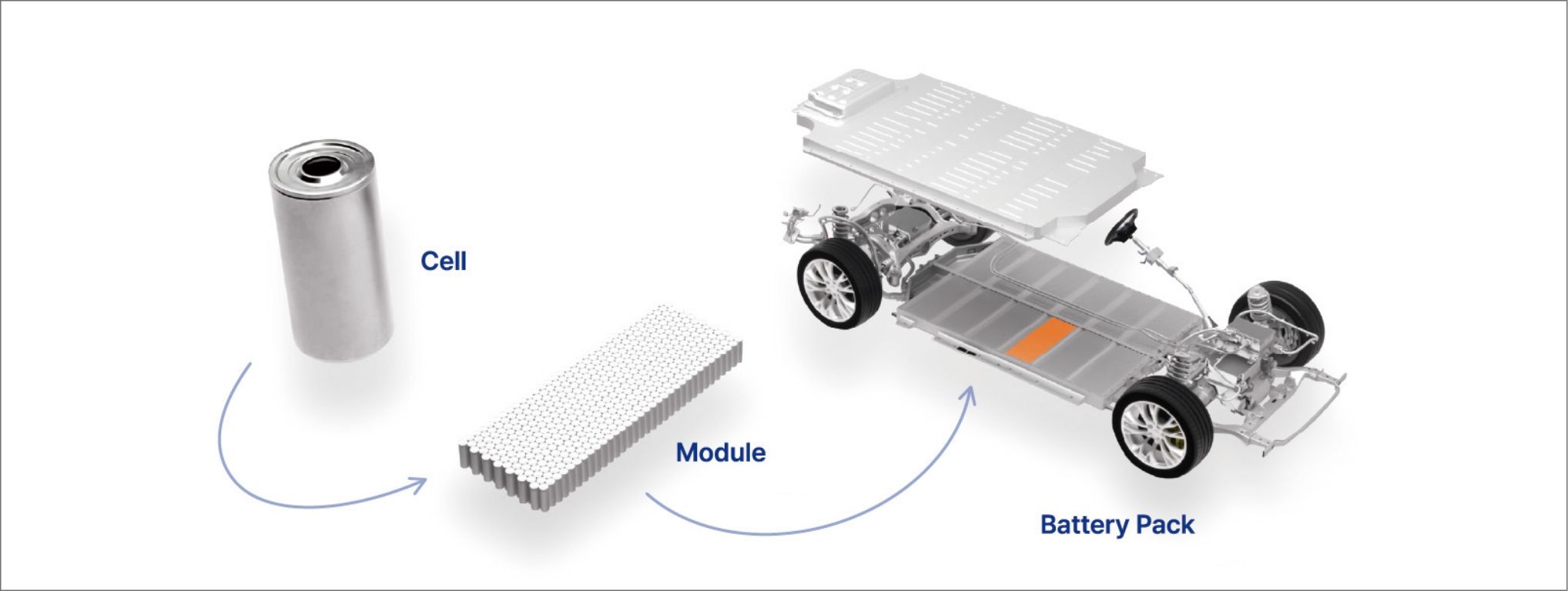

How is a Cylindrical Battery for Electric Vehicles Constructed?

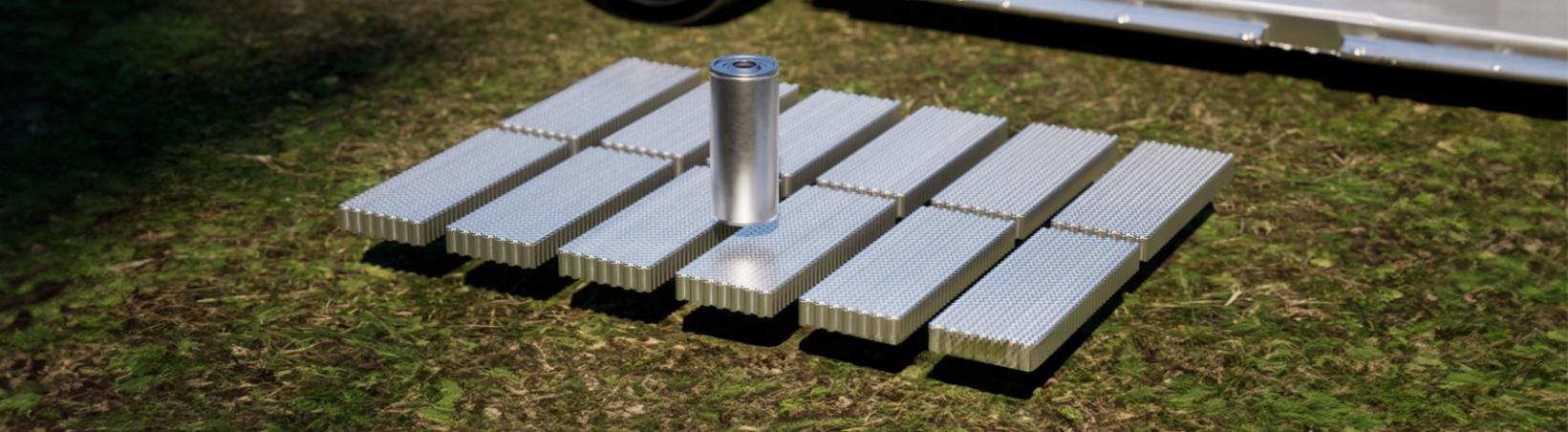

A single cylindrical battery wrapped in a nickel-plated steel is called a Cell. When Cells come together, they form a Module, which combines to create the Battery Pack used in electric vehicles. The number of Cells and Modules varies depending on the type of vehicle.

Is Dongkuk Industries' DiKel Only Used in Electric Vehicles?

DiKel, known for its excellent corrosion resistance and durability, is used in cylindrical battery cases.

These robust batteries are crucially utilized in environments requiring high stability.

They are also used in electric vehicles and personal mobility devices such as electric bicycles, scooters, and power tools. Dongkuk Industries' DiKel will enhance your daily safety.

Electric Vehicle Batteries

Personal Mobility

Power Tool Batteries

Dimension

(mm)

| Thickness | Width |

|---|---|

| 0.2 ~ 1.0 | 25 ~ 1,219 |

| C | Si | Mn | P | S |

|---|---|---|---|---|

| Max. 0.08 | Max. 0.03 | Max. 0.40 | Max. 0.02 | Max. 0.03 |

| T. S (Mpa) | Y.P (Mpa) | Elongation (%) |

|---|---|---|

| Max. 430 | Max. 370 | Min. 25 |

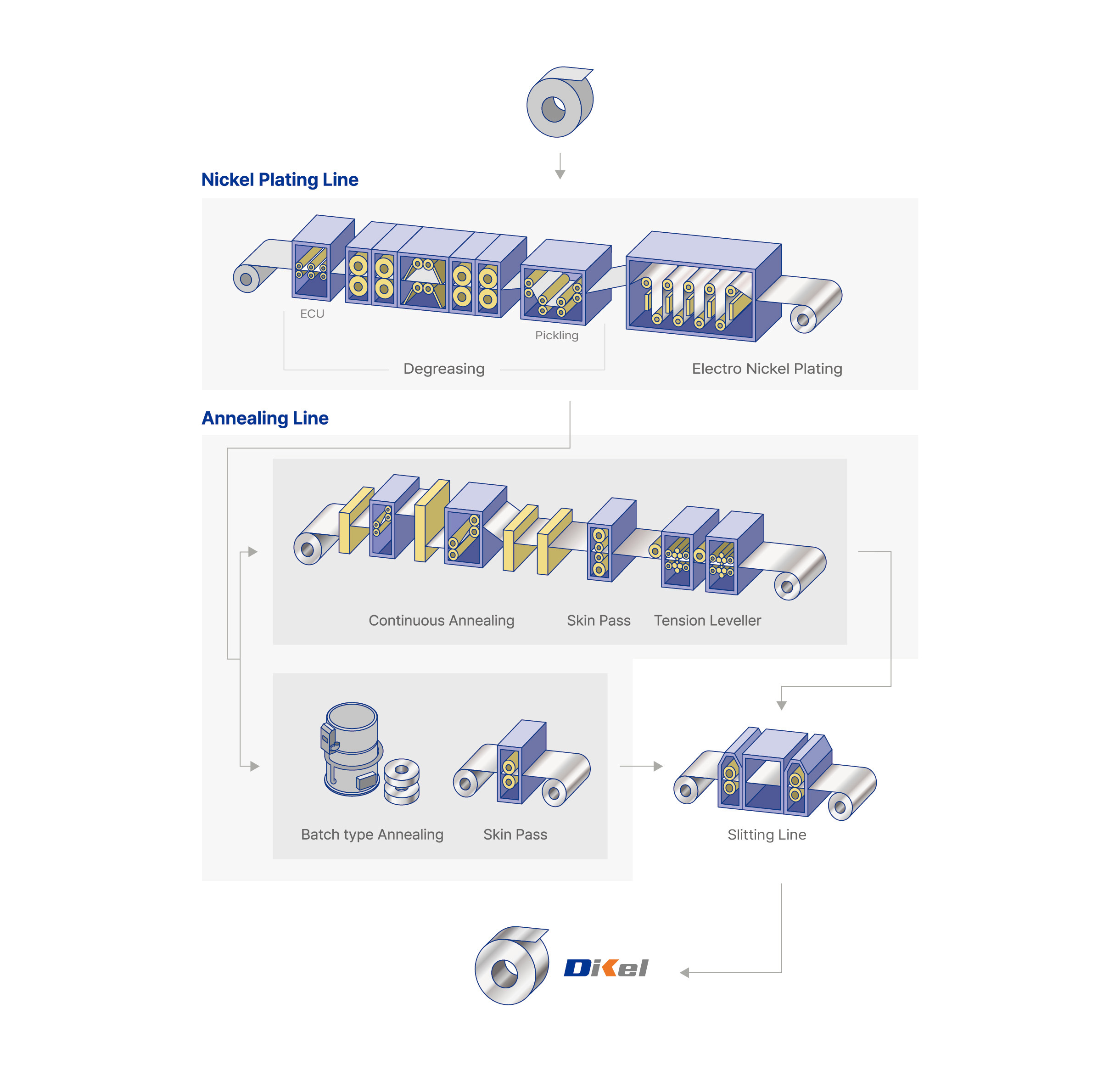

Nickel Plating Line

| Category | Remarks |

|---|---|

| Input Thicknes (mm) | 0.2 ~ 1.0 |

| Input Width (mm) | 750 ~ 1,219 |

| Capa. (Ton/年) | 80,000 (130,000) |

Slitting Line

| Category | Remarks |

|---|---|

| Input Thicknes (mm) | 0.2 ~ 1.0 |

| Input Width (mm) | 750 ~ 1,219 |

| Output Width (mm) | Min. 25 and above |

| Capa. (Ton/年) | 130,000 |

Annealing Line

| Category | Atmosphere Gas | Input Thicknes (mm) | Input Width (mm) | Capa. (Ton/年) | Remarks | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Batch | H 100% | - | 150 ~ 1,320 | - | ||||||||

| Continuous* | H, N Mix | 0.2 ~ 1.0 | 750 ~ 1,219 | 80,000 (130,000) |

* Continuous

|

Product Application

A Nickel-plated steel, known for their exceptional corrosion resistance and durability, is used in manufacturing battery cases for electric vehicles, personal mobility devices, ESS, and power tools used in environments requiring high safety.

Electric Vehicle Batteries

Personal Mobility

Power Tool Batteries

Download PDF

Download PDF