Hardened & Tempered Steel

Product Grade

Product Specifications

Product Application

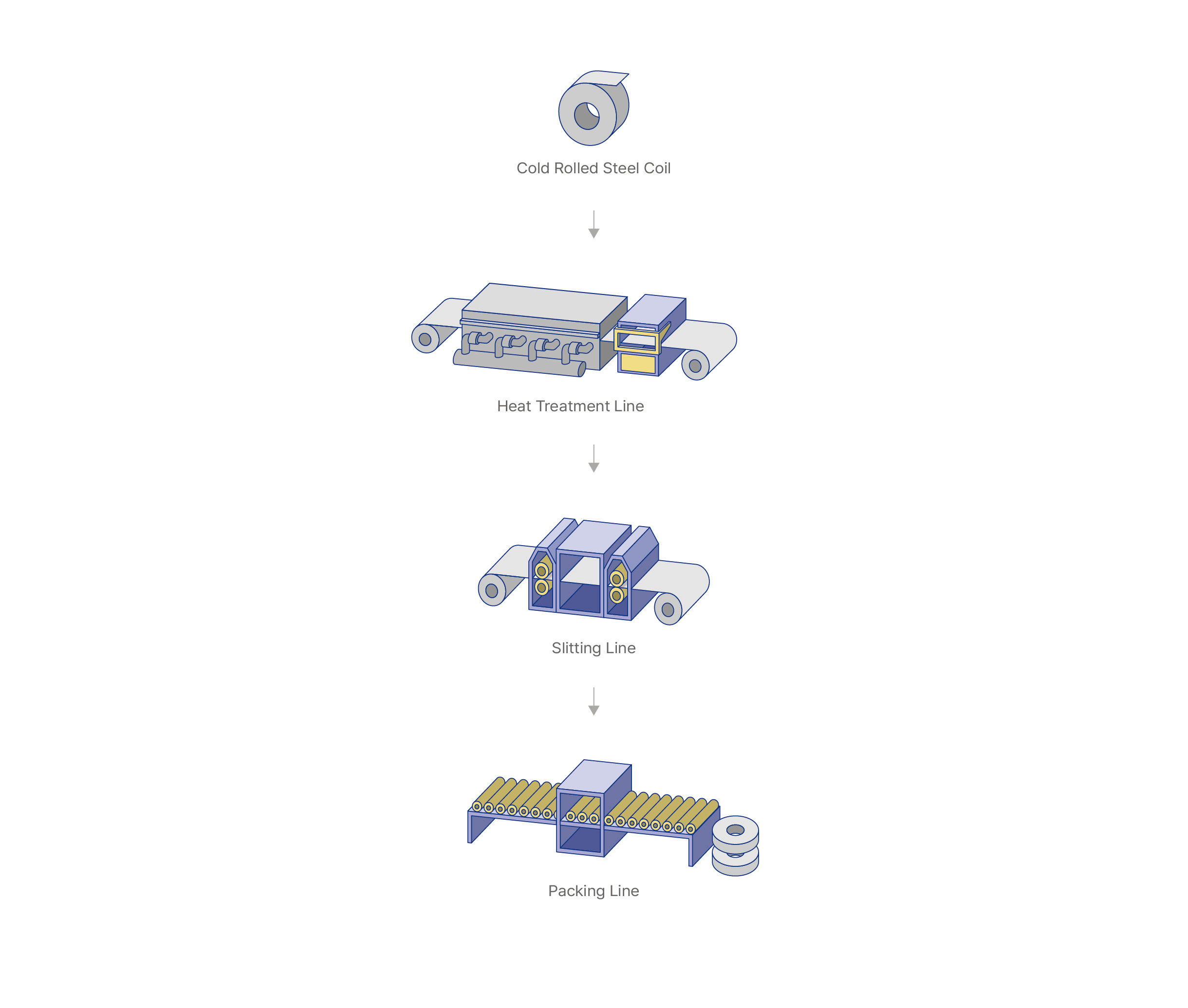

Production Process

| Grade | Microstructure | Tolerance ※ Varies with thickness |

|---|---|---|

| S35C~S75C | 1. Martempering (Martensite) Bright / light yellow Surface 2. Austempering (Bainite) Grey – Blue Surface 3. Patenting (Sorbite) Bright Surface |

1600~2300N/mm2 (Max. ±30) |

| SK | ||

| SCM | 1300N/mm2 (Max. ±40) |

|

| SKS | ||

| Spring | 1100~1300N/mm2 (Max. ±40) |

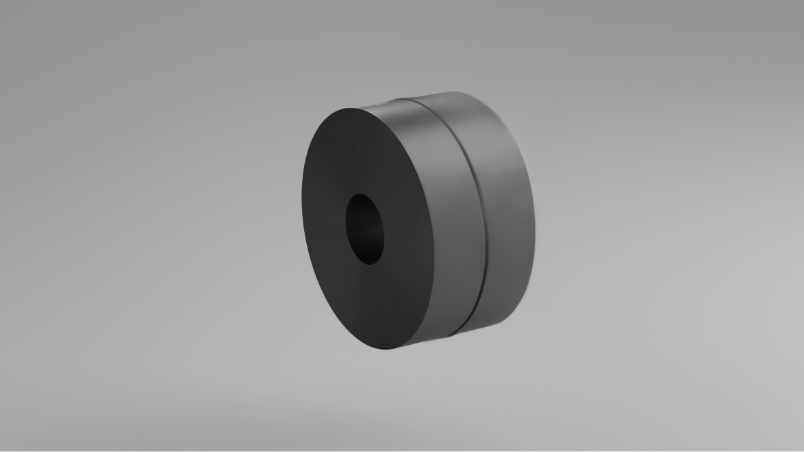

Dimension

(mm)

| Thickness | Width |

|---|---|

| 0.1 ~2.5 | 80~450 |

Martempering : Martensite

Martempering : Martensite

Flapper Valve

Flapper Valve

Shock Absorbers

Shock Absorbers

Saw Blades (Wood / Stone Processing)

Saw Blades (Wood / Stone Processing)

Circular Tanks

Circular Tanks

Austempering : Bainite

Austempering : Bainite

Precision Automotive Parts

Precision Automotive Parts

Leather and Paper Punching Dies

Leather and Paper Punching Dies

Molds and Fabric Cutters

Molds and Fabric Cutters

Patenting : Sorbite

Patenting : Sorbite

Vehicle Safety Belt Springs

Vehicle Safety Belt Springs

Cable Drum Springs

Cable Drum Springs

High-Strength Helical Springs

High-Strength Helical Springs

Download PDF

Download PDF